Cylindrical Battery Welding

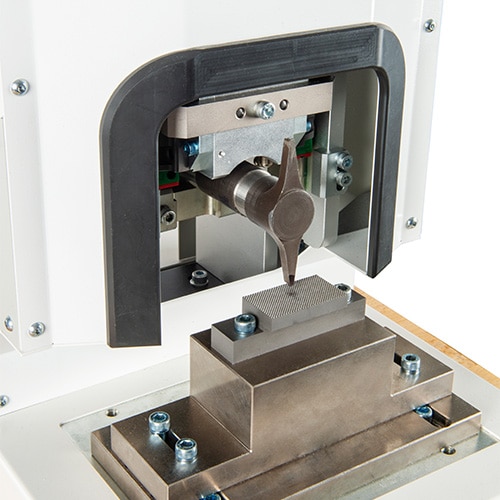

For delicate applications, TECH-SONIC introduces its 900W small spot welder machine, model US-935SH. It possesses many of the same features as its 3.6kW CLC companion in a scaled-down version to weld with much smaller delicate parts. This cylindrical battery welding machine is able to detect single missing or added foils and tabs in a stack and has a smaller weld area for precision welding. The lower power and higher frequency make this ultrasonic cylindrical battery welding machine the ideal solution for batteries used in mobile phones, credit cards, and other smaller electronic devices.

TECH-SONIC has gone beyond the latest ultrasonic metal welding technology by adding servo mechanism control to ultrasonic welding. Thus, producing a closed-loop control welding process that responds to the various dynamics of today’s critical welds. Moreover, this CLC cylindrical battery spot welding machine provides accuracy, repeatability, and reliability. Specialized in the welding of copper or aluminum foils, which are a base material as anode and cathode in lithium battery designs.

CLC Advantages for Battery Welding

TECH-SONIC’s patented servo control ultrasonic welding process (Multi-step process) allows the user to apply the proper amount of force and energy to the weld at the appropriate time. By being able to control these specific welding parameters, this CLC cylindrical battery spot welding machine enables the users to create precise, consistent, and repeatable welds.

Features and Benefits of Closed Loop Control Technology for Battery Welding

- Ability to detect single missing or added foils and tabs in a stack

- Capability of over 20 weld steps

- Measurement of pre weld and post weld height (CLQC)

- Knurling lasts longer due to multi-step process

- Ability to change force and amplitude during weld cycle

- Consistent measurement and ultrasonic output produce high cPk values

- Lower energy/ lower operational cost

For more technical information, please download our brochure

Need a solution for Standard Power Heavy Duty Applications?

See our US-3620SH model

CLC Pouch/Prismatic

Battery Welder

US-3620SH

Need a solution for High Power Heavy Duty Applications?

See our US-5020SH model

CLC Pouch/Prismatic

Battery Welder

US-5020SH